Lithium-Ion Battery Manufacturing Process Basics

The lithium-ion battery manufacturing process is often presented as a simple sequence of steps. In reality, it is a tightly coupled system of unit operations where early decisions strongly constrain what is possible later in production.

Understanding how lithium-ion cells are manufactured is less about memorizing individual steps and more about recognizing how materials, equipment, and cell format choices interact across the entire process flow.

This article provides a practical overview of the lithium-ion battery manufacturing process, with particular emphasis on electrode fabrication — the stage where many downstream outcomes are quietly determined.

Cell Format as a Starting Point in the Manufacturing Process

The lithium-ion battery manufacturing process begins long before electrodes are coated. One of the earliest and most consequential decisions is cell format selection.

Commercial lithium-ion cells are commonly produced in three formats:

cylindrical

prismatic

pouch

Each format reflects a different balance of manufacturability, energy density, mechanical robustness, and cost. Cylindrical cells remain widely used because of their structural stability and high manufacturing efficiency. Prismatic and pouch formats offer improved space utilization at the pack level but introduce additional complexity during cell assembly and handling.

Emerging designs in recent years — including large-format cylindrical cells and long prismatic “blade” cells — further illustrate how cell format, chemistry, and mechanical design are tightly linked. These choices directly influence electrode dimensions, coating widths, line speeds, drying requirements, and inspection strategies later in the lithium-ion battery manufacturing process.

There is no universally optimal format — only trade-offs that must be carefully considered.

Major Stages of the Lithium-Ion Battery Manufacturing Process

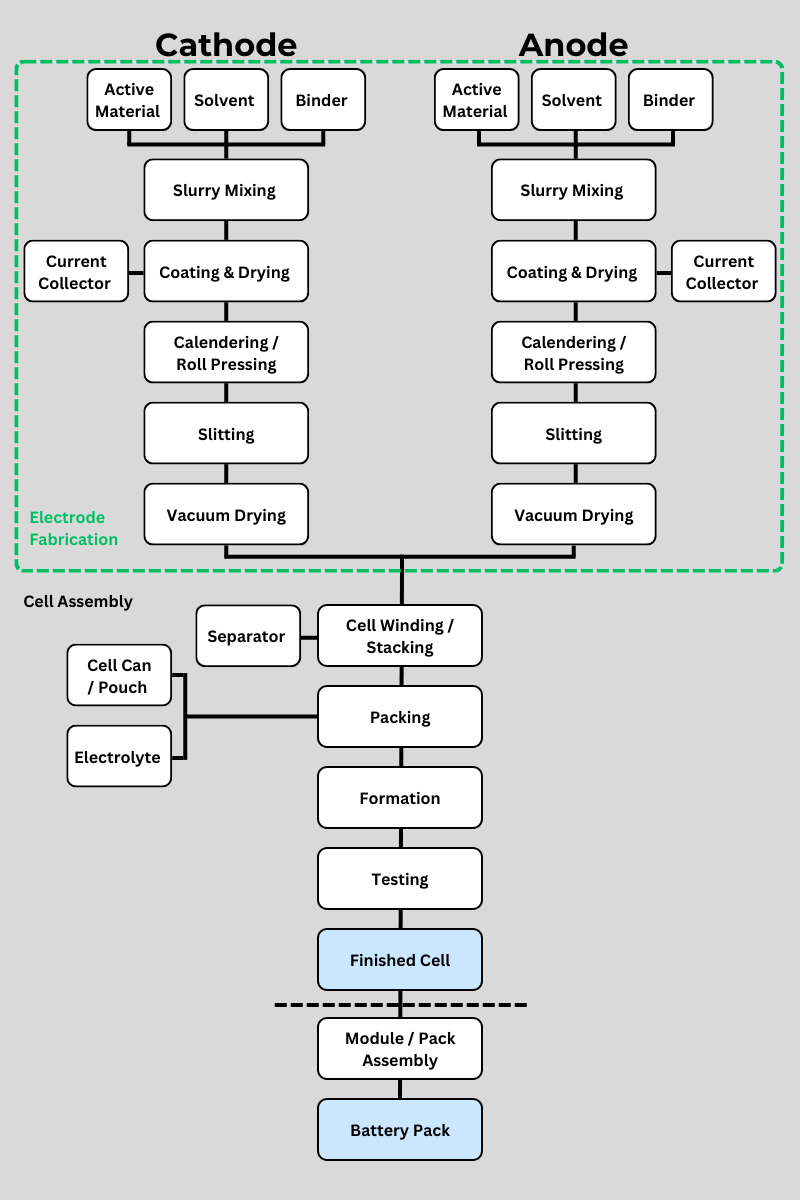

At a high level, the lithium-ion battery manufacturing process can be divided into four primary stages.

1. Electrode Fabrication

Electrode fabrication converts raw materials into functional anodes and cathodes. The output at this stage are "mother" or "jumbo" rolls of coated electrode on thin foil current collectors, with the anode coated on copper foil and the cathode coated on aluminum foil.

Core unit operations include:

slurry mixing

electrode coating and drying

solvent recovery

calendering

slitting or punching

secondary "vacuum" drying

This stage establishes many of the physical and electrochemical properties of the final cell. Thickness uniformity, porosity, adhesion, and defect levels introduced during electrode fabrication propagate directly into cell assembly, formation behavior, and long-term performance.

Figure 1: Lithium-ion battery manufacturing process flow chart showing electrode fabrication, cell assembly, formation, and pack assembly

2. Cell Assembly

During cell assembly, prepared electrodes are converted into physical cell structures through:

electrode notching

stacking or winding

packing into housings

electrolyte filling

The tolerances achievable during this stage are heavily dependent on electrode quality and consistency. Variability introduced during electrode fabrication limits how robust cell assembly can be at scale. Defects such as: edge beads, voids, and adhesion/cohesion failure can show up at this stage, contributing to production scrap.

3. Cell Finishing and Formation

Cell finishing includes initial charge–discharge cycles used to form the solid electrolyte interphase (SEI). While formation stabilizes the electrochemical system, it also exposes weaknesses created earlier in the lithium-ion battery manufacturing process.

Issues that appear during formation often originate upstream, particularly in coating uniformity or electrode structure.

4. Pack Assembly

In the final stage, individual cells are assembled into modules and packs, integrated with mechanical structures and battery management systems (BMS). At this point, variation between cells becomes a system-level challenge rather than a process-level one.

Why Electrode Coating Is Central to Lithium-Ion Battery Manufacturing

Across the entire lithium-ion battery manufacturing process, electrode coating consistently emerges as one of the most difficult steps to scale.

Modern electrode coating lines share a common architecture:

material unwind and rewind

fluid delivery and slot die coating

drying sections

inline gauging and inspection

Different coating configurations — single-side, tandem, or simultaneous two-side coating — are selected based on chemistry, throughput targets, and capital constraints. Large-scale manufacturing lines may operate at tens of meters per minute, across foil widths up to 1.5 meter, with dryer lengths approaching 100 meters long.

At this scale, small inconsistencies in slurry preparation, coating setup, or drying assumptions can quickly translate into scrap, instability, or narrow operating windows. When running at coating line speeds in the 60-80 meter per minute range, product not within spec or containing defects can add up quickly leading to high scrap rates.

Inspection and Control in Production Reality

Inline inspection systems, particularly thickness and mass gauging, are essential components of the lithium-ion battery manufacturing process. They allow manufacturers to:

detect defects early

control coating uniformity

maintain yield during production ramp-up

However, inspection alone does not solve process instability. Gauges can identify when a problem exists, but not why it exists. In practice, many coating challenges trace back to early development assumptions rather than inspection hardware limitations.

Often defects seen on the "dry" end of the machine or at calendering did not originate there. The root cause can be traced further upstream. Process engineers need to look at patterns and sources of variation — starting with the drying profile, moving backward to the coating process parameters, slot die setup, fluid delivery system status and back further to slurry mixing beginning with raw material weighing. Root cause thinking is the key to not just fight defects, but tracing them to the source.

A Core Manufacturing Principle

One principle consistently holds true across lithium-ion battery manufacturing:

The cell format and chemistry dictate the electrode coating requirements — not the other way around.

“The cell format and chemistry dictate the electrode coating requirements — not the other way around.”

As manufacturers push toward higher throughput and faster production ramp-ups, electrode coating remains a primary bottleneck. Reducing scrap and stabilizing production requires understanding how early equipment and process decisions shape downstream outcomes.

In Closing

This post is intended to establish a shared baseline for understanding the lithium-ion battery manufacturing process.

Future articles will examine individual steps in greater depth, particularly electrode coating, drying, and scale-up, with a focus on how manufacturing systems behave under real production constraints rather than theoretical assumptions.

For engineers and technical managers working in lithium-ion cell production, this foundation is critical to understanding how each unit operation is linked on a system level.